On Wednesday 9/5/2018 we went by bus to color pack company (printing company) that is located in Nyiregyhaza city

the trip started at 8:00 am we went by bus then at 9:00 we stopped at a gas station to get some think to drink and we arrived to the company around 9:30

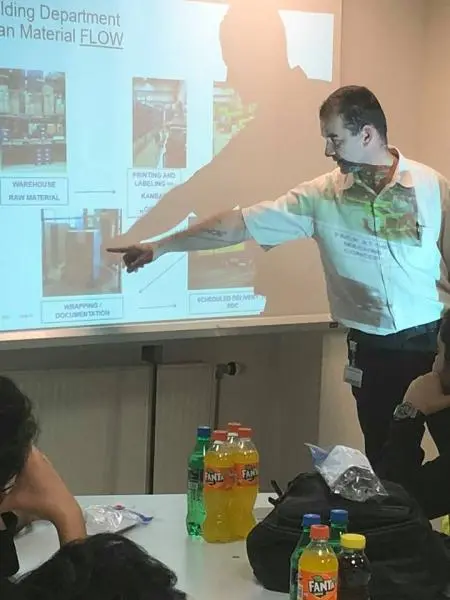

at first we went to a meeting room and met a company representative that told us about the company in general then we split into two groups I was in group two which went down to the factory and the representative started explaining to us about each machine and each step for producing the printed material ( labels for eggs and and other products and some some packaging materials ) and then he explained to us the income and profits of the company ( the income for the company was 6 million euros ) after we finished the tour in the factory we went back to the meeting room and group 1 went to the factory and then the representative started explaining to us about the quality management in the company and he explained to us about the salaries in the company (the system was that you have a basic salary and if you did extra work you will get extra money and if you did a mistake your basic salary will not be affected ) and after that the students started asking questions about the management of the company and the representative explained them nicely after that we went out took some pictures and after we went back to the bus

Development suggestion: try to find new customers through social media

Laith Mershed

We went to a field trip with the basics of quality management teacher and the students to visit the company “color pack” to see how is the quality management methods and principles are applied in the real life companies and “color pack” was a great example for that.

After we arrived to the company, we found a great example of greeting and hospitality.

The trip inside the company started with the “prepress” phase which includes designing the lables and the advertisement in a digital format to be printed on paper In a later step.

After the prepress phase the real printing starts using press printing machines which has a very high pressing capacity and give very saturated colors and very accurate prints.

The printing capacity can reach up to 16,000 copies per minute which was really amazing to watch and see how fast these machines can go.

During the printing phases a worker is checking the quality of the products and sees if there is a need to stop the production or modify the process to get the best quality possible.

The last step is cutting the advertisement papers into the shape requested by the customer and packaging the final products to be sent to the customer.

It was a great day visiting this nice company and I honestly I wished to spend more time there.

A small suggestion from me is that the final products should be organized in a better way because they were taking a very big space, they must use the storage area more efficiently.

At last special thanks for Mrs Andrea Matkó for her effort to organize this trip and for the workers in “color pack” for their welcoming especially the CEO who was a very nice and friendly guy and was open to every question we had

we leand to many things there about the company itself , the managers and the employees , How the treat there employees , how they motivate them to keep the work in high quality , how to deliver the product at the specific time and many other things about the managment , how they fix the problems that face them during the daly work , and how they use the key principles of the real managment

It was a nice trip we injoyed it and it was a real example about interesting learning from a great teacher

Thank you so much for everything you did for us.

Sakher Obeidat

In (9-5-2018) we were in the educational trip , with Basics of quality management Doctor: Matko Andrea and the student to Visit the Company in Nyiregyhaza (100 km from Debrecen )

The Company name : Color Pack , this company was a very good example to understand How the quality management is going on .

We start the trip inside the company by step by step how they make the colours paper , we start to see how the designing the labels after that the printer start to print the labels by very high quality and saturated colour ,

During the trip inside the company , every few minutes some worker comes and start to check the printed papers to know the quality of it and , if there is some wrong immediately they put the papers in the rubbish .

After that The cutting machines start to cut the paper into shapes requested the customer and cover the goods and sent the products to the customer .

i saw there is a lot of paper waste it ( bad quality or something wrong ) my suggestion is that buy a machine that knows if there is wrong or different quality immediately stopped to fix the problem and in that case they will not waste a lot of paper and color painting .

Specially thanks for Dr Matko Andrea for this trip because we understood how the quality management and the 5s work.

Zumot Beshara

Last week, on 2018.05.09, Dr. Matkó Andrea take us to visit Color Pack Zrt. I am very happy to participate in this field trip.

When we arrived at the destination, they were very friendly and introduced us to the company.

The company specializes in the manufacture of paper-based packaging materials and specializes in the production of magazines, books and unique advertising materials.

After some visits, I was very interested in their automation operations and I also realized that the cooperation among employees is very important for the production line and the company.

We can see that the company can provide quality services and gradually increase customer confidence. Because of this, the team of 80 people can create 1.6 billion forints of wealth a year.

Developemt suggestion

1. Establish company image and expand market.

2. Some product lines can use automation or mechanization to increase efficiency, such as product packaging.

3. As they say, focus on improvement.

4. Improve management systems to increase efficiency and reduce costs.

Shi Weimeng

We went on Wednesday 9/5/2018 to the color pack company we were lucky as it was a sunny day. We started the trip at 8:00 am and on our way at around 9:00 we stopped at Macdonald’s we spent there around 15 minutes then continued to the company and at around 9:30am we reached it.

A representative of the company met us at the entrance and welcomed us, he took us to a meeting room where we were offered some snacks and soft drinks, he explained to us what we were going to do and give us some information about the company, later we were divided into two groups each group had it’s own guide we were divided according to our birth date those who were born on an even date were group 1 and those who were born on a odd date were group 2. I was in group 2 and our guide was the owner of the company.

first we were taken downstairs to the factory the workers were very nice and helpful they answered all our questions if they were asked, we were shown the process of production step by step machine by machine and it was explained to us in details in short there are three main stages of printing excluding the designing, first is the printing machine which is the main procedure, there are 3 big machines in the company the newest and latest version was bought this year for around 2.5 million euro it can print and make more complicated tasks than machine which was brought in 2008,after the printing process there is the cutting machine which separates the printed materials from the waste, after that the final main step is the packaging.

After that we were taken back upstairs to the to the designing department where we were shown the offices and where the designing and preprinting procedure is done.

afterwards we were taken back to the meeting room where we meet the first group again and could grape some more snacks and we had about 30 minutes to ask questions and the company representative along with the owner of the company took turns to answer them.

The company has some interesting background it was made in the soviet era so it belonged to the government and after that is was bought by the workers of the company so in the beginning it had 113 owners reduced to 13 now with most shares being owned by our guide as he explained to us, there profits are good even though they have many expanses as they make annually 6 million euro.

The company have around 81 employees and they have pretty nice policy towards them, for example if the worker makes a mistake he will punished but his base salary will not be affected and the company gives extra money to those workers who out perform the others which motivates everyone to do his best.

The company still have room for improvement and growing, for example I would suggest:

1.Business website design

2.specilazie in short-run printing

3.offer a unique paper type

4.help your costumer grow their business with direct mail

All in all, the trip was a very nice experience rich in knowledge and fun, everybody had great time and at the end of the day we made some unforgettable memories and learned some valuable information.

David Haddad

The trip to the color pack was Great experience to see how quality management is applied in printing company. It was great to see the different departments work together to make sure the quality standards is set. The different department had different quality and how they followed the system so they can keep the right quality up to mark.

It was great to see that they had a chart for every employee as their performance check with their efficiency list. The company did well to offer bonuses on the employee performance. They even had a right quality police according to ISO standard.

The Development suggestion for the company.

To have better system collecting and use more recycled paper in printing and also look for renewable energy souces for the printers.

Shah Neel Mineshbahi

Color Pack has Offers design and marketing expertise and produces printed collateral for local businesses. They always figured that putting people before profits just made good commonsense. they are specialized in producing catalogues, magazines, brochures, leaflets, books and unique commercial products beside packaging materials. Thanks to their technical background and their professional staff they provide world-class service. them products are manufactured using cutting-edge technology coupled with them staff’s innovative professional knowledge. them references, special technology and security preparedness guarantee that we can offer the best possible product for our customers. their success is based on increasing our clients’ trust in us by meeting their demands providing quality service within deadline.

Development suggestion

In my opinion the color pack it can improve in different position of the work and it can make more business activities and get more revenues per a year like:

- Adopt new technology and process during manufacturing

- Social media marketing

- Cross media marketing

- Pay well and keep the workers motivated

- Costumer storefronts

The most important they should have a big deal with big companies out of Hungary.

Ali Kahtan Naseer

Objectives of the field visit:

To improve the technical skills of students.

To understand and identify the difficulties/ barriers in practical work in the fields.

To show the technical standard to improve or strengthen their performance and plan for the next necessary action as needed.

Methodologies:

Direct observation.

Explanation on graphs.

Interview with staff.

Result:

A better understanding of who quality management works.

Understand the company ways of solving problems.

Teamwork and time management of the workers.

Information about the economical side of the company.

Issues/ Challenges:

Keep following the time table of production.

Trends in consumer spending.

The state of the global economy.

New technology and the speed of change.

Changing customer expectations.

Globalization.

Environmental concerns.

Suggestion:

Expanding print services.

Digital transformation.

Adapting to "the new economy".

Ghiath Chukr

Color Pack has a distinctly human approach to the printing business. They always figured that putting people before profits just made good commonsense. they are specialized in producing catalogues, magazines, brochures, leaflets, books and unique commercial products beside packaging materials. Thanks to their technical background and their professional staff they provide world-class service. their main task is not only to keep up with but to take the lead in introducing new technologies, products and services. their success is based on increasing our clients’ trust in us by meeting their demands providing quality service within deadline

Development suggestion

In my opinion the color pack should do more printing business activities to develop the company and get more revenues per a year like:

- Graphic Design Services

- Promotional Products

- Costumer storefronts

- Cross media marketing

- Newsletters

- Trade show displays

The most important they should have a big deal with big companies not only in Hungary also with different countries.

Abdulmalek Shaaban